Характеристики товара

1. Радар миллиметровых волн имеет точность измерения до ±1 мм, а слепая зона измерения составляет 10-50 мм.

2. Меньший размер антенны для удовлетворения большего количества рабочих условий.

3. Многолинзовые антенны, угол излучения 3°, более концентрированная энергия, более сильный эхо-сигнал, более высокая надежность по сравнению с другими радарами в тех же промышленных и горнодобывающих условиях.

4. Обладает более сильной проникающей способностью и может нормально использоваться даже при наличии адгезии и конденсата.

5. Динамический диапазон сигнала больше, а измерение сред с низкой диэлектрической проницаемостью более стабильно.

6. Несколько режимов измерения, время отклика радара менее 1 с в режиме быстрого измерения.

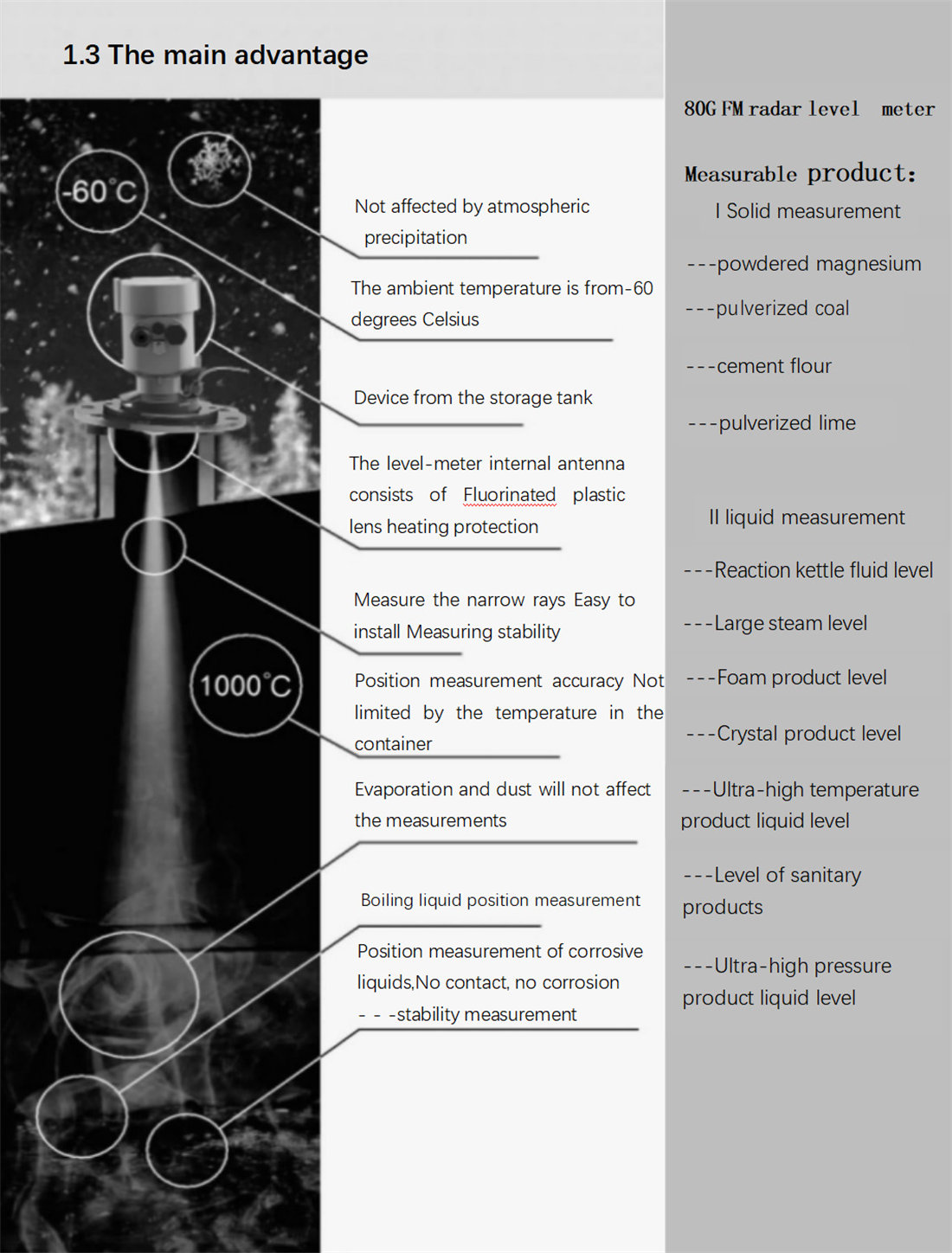

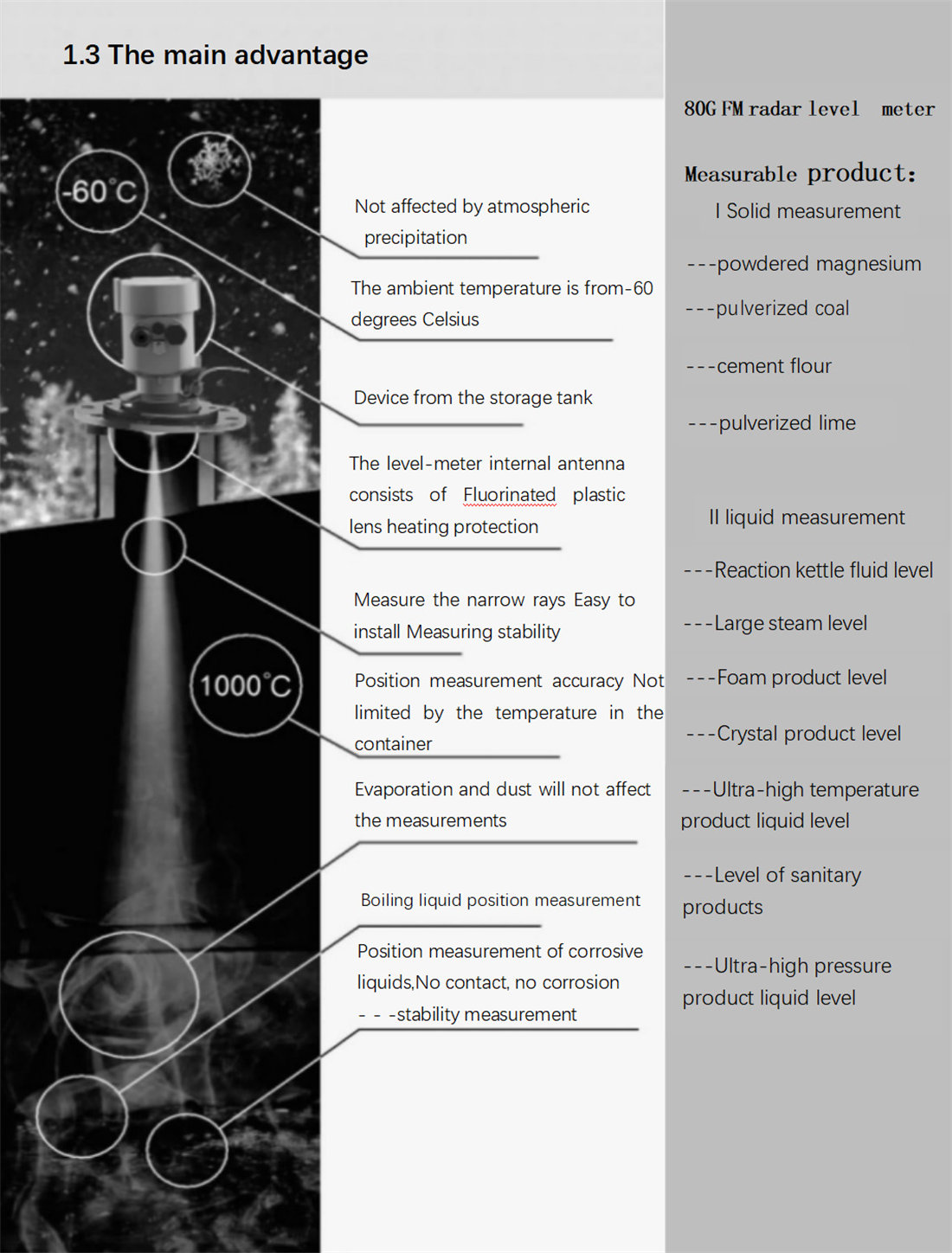

Преимущества продукта

Параметры продукта

|

принцип измерения

|

2 / 4 проводной, FMCW радар

|

|

диапазон частот

|

W-диапазон [76-81 ГГц]

|

|

максимальный рабочий диапазон

|

Максимальное значение - 120 метров

|

|

точность измерения

|

±1 мм

|

|

форма вывода

|

4~20 мА, RS-485

|

|

режим связи

|

HART, MODBUS

|

|

Диапазон питания

|

24±6V

|

|

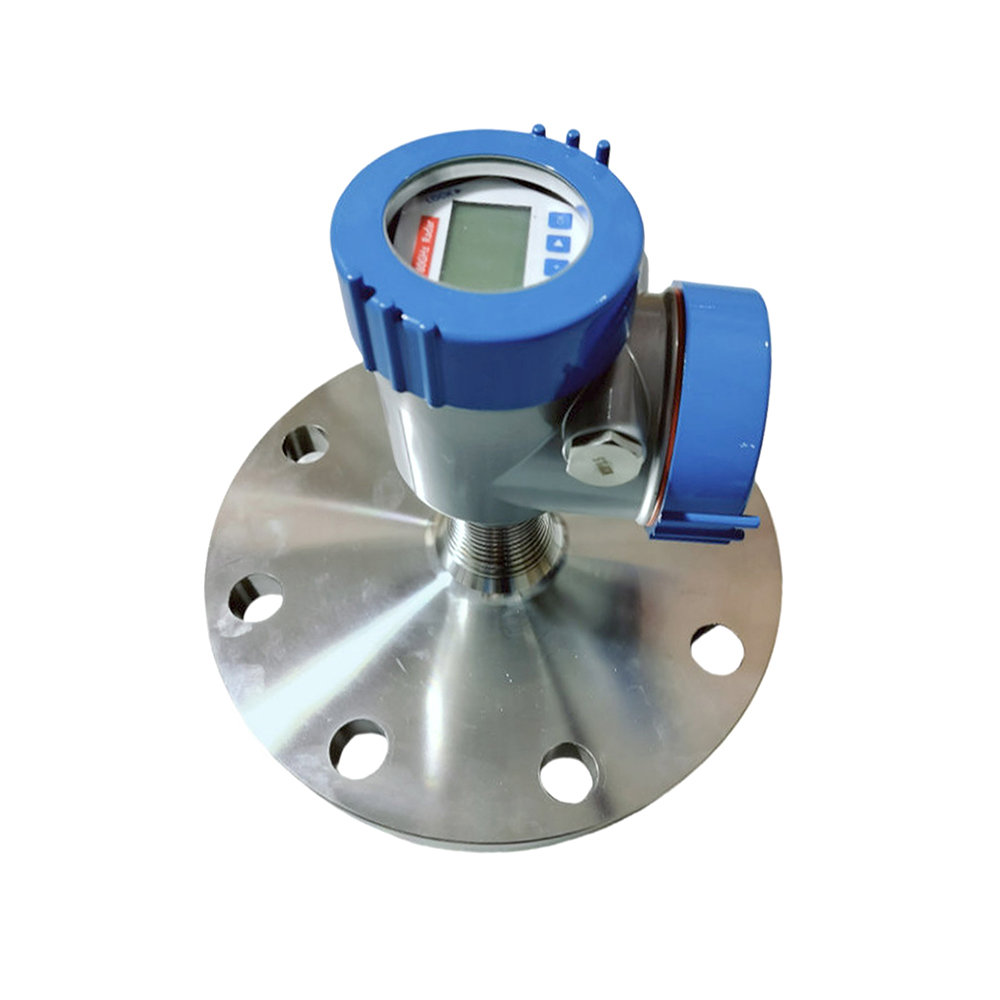

Форма антенны

|

Рупорная или линзовая антенна

|

|

Технологическое соединение

|

Фланец начинается от DN50, резьба - от G3 / 4

|

|

Давление процесса

|

-1...20 бар

|

|

Температура процесса

|

-40~+200℃

|

|

Температура хранения в окружающей среде

|

-40~+80℃

|

|

инкрустация

|

Литьевой алюминий / нержавеющая сталь

|

|

Уплотнение между корпусом и крышкой корпуса

|

силиконовая резина

|

|

Окно в шкафу

|

поликарбонат

|

|

клемма заземления

|

нержавеющая сталь

|

|

Кабельный ввод / штекер

|

1 глухой блок M20×l.5/1 M 20xl.5 кабельный ввод

|

|

соединительная клемма

|

Сечение провода 2,5 мм²

|

|

сигнал пробоя

|

Выходной ток остается неизменным;21 мА;3,6 мА

|

|

время интеграции

|

(0~20)s,tunable

|

|

зона затухания

|

0,05 м/0,2 м

|

|

Интервал измерения

|

Около 1 секунды (в зависимости от настроек параметров)

|

|

управляющее время

|

Около 1 секунды (в зависимости от настроек параметров)

|

|

относительная влажность

|

˂ 95%

|

|

Ударопрочный

|

механический удар l0m/s² , (10~150)Гц

|

|

Уровень защиты

|

IP67

|

|

классификация по степени опасности

|

ExdiaIICT6

|

|

способ установки

|

Резьбовые или фланцевые

|

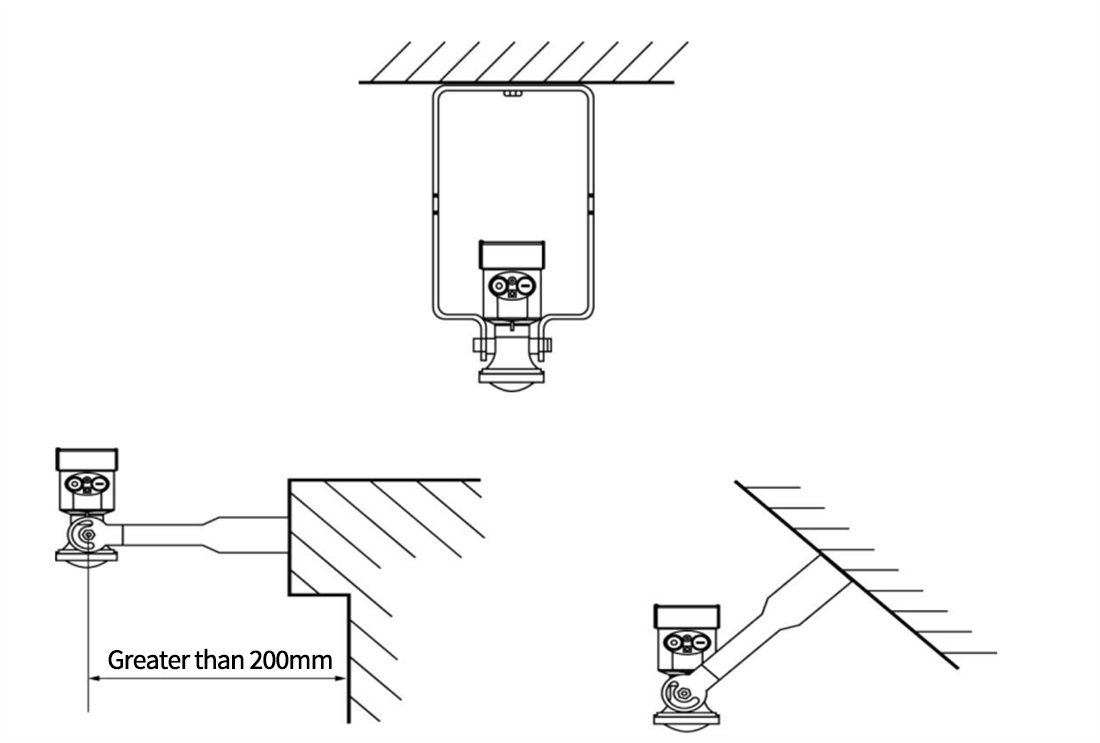

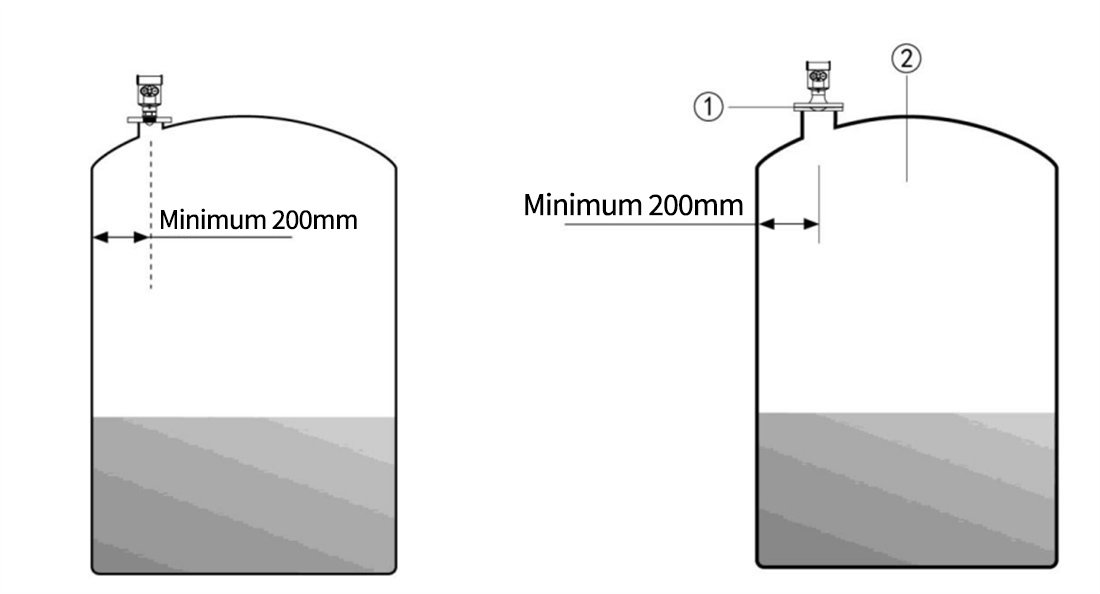

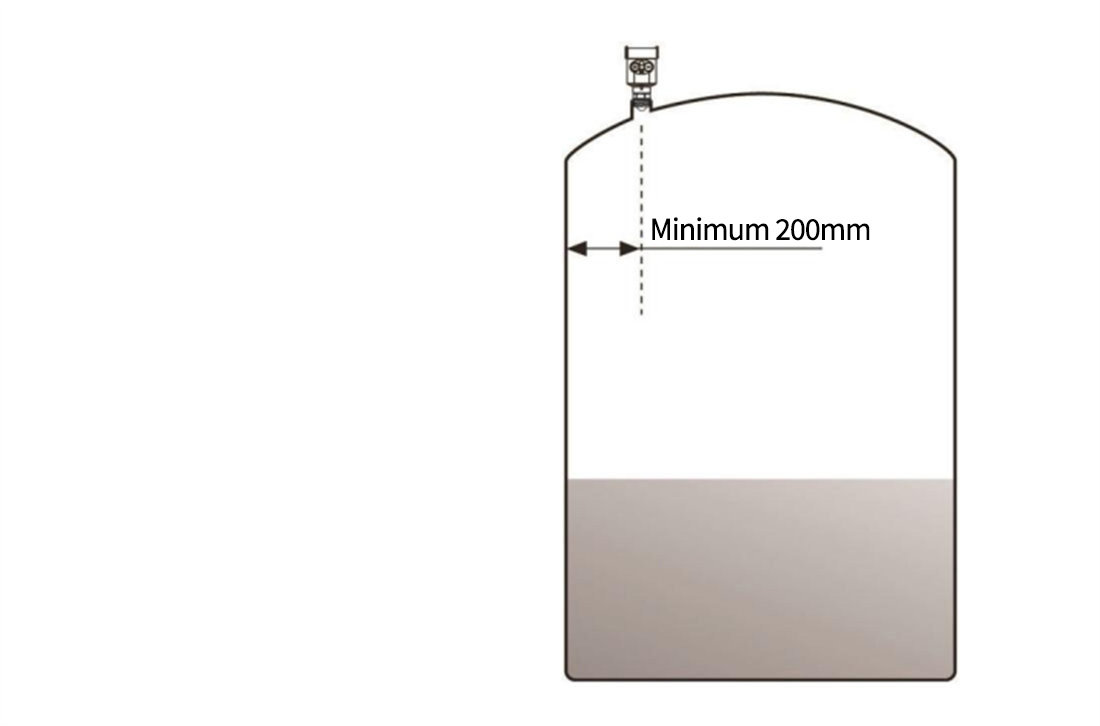

Способ установки 1: резьбовая установка

Способ установки 2: установка фланца

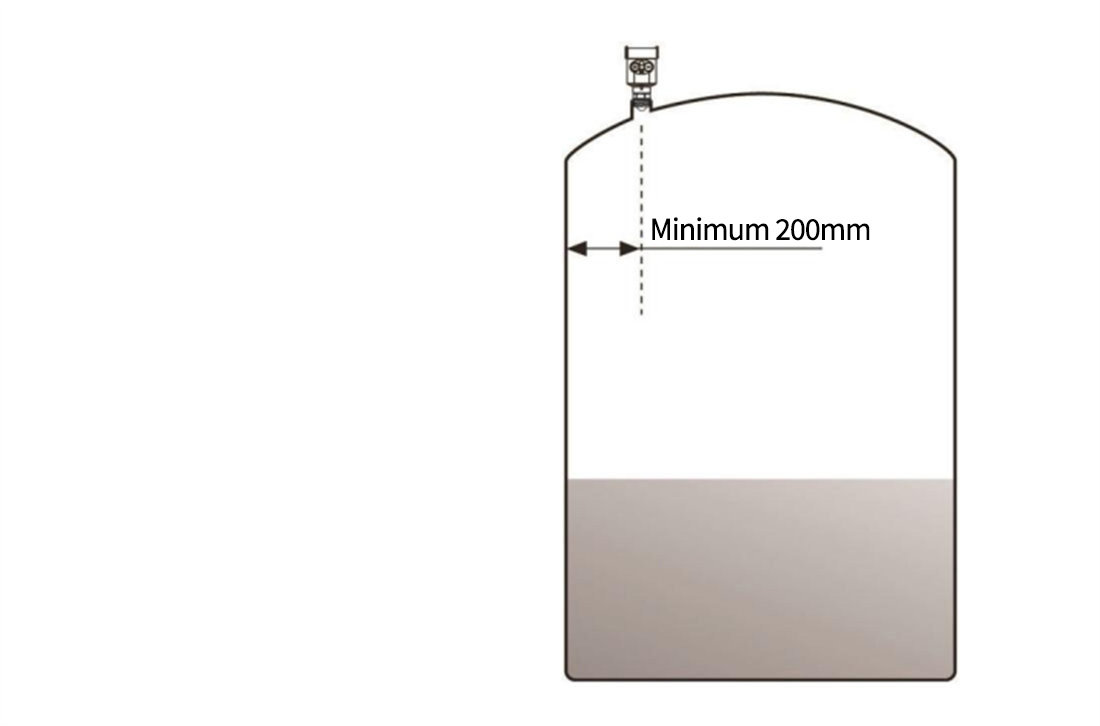

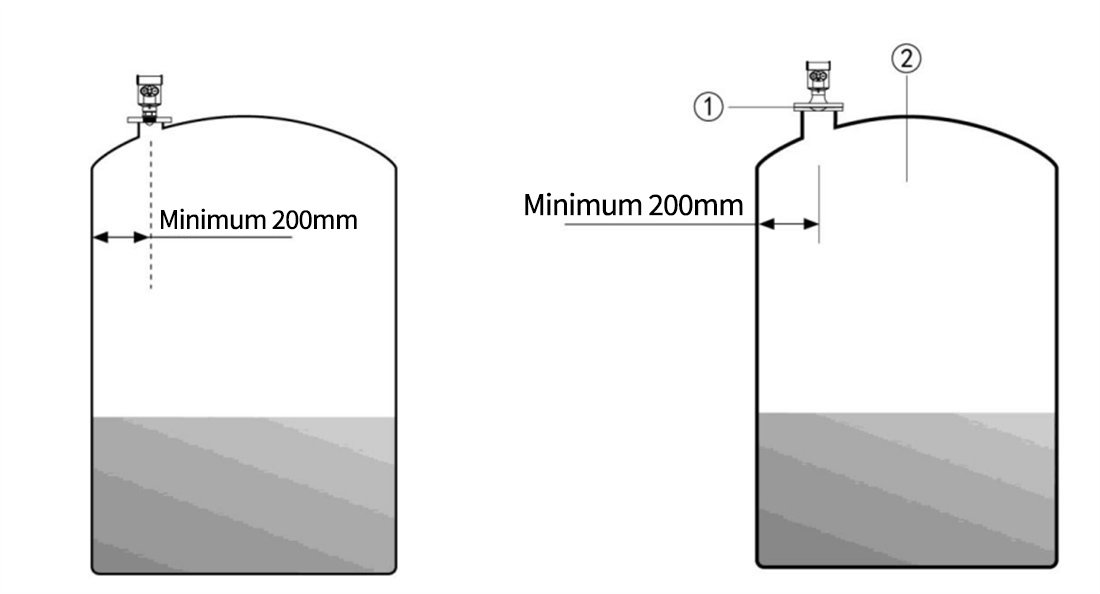

При фланцевом монтаже минимальное расстояние между прибором и стенкой резервуара должно составлять 200 мм.

① Контрольная поверхность ② Центр контейнера или ось симметрии

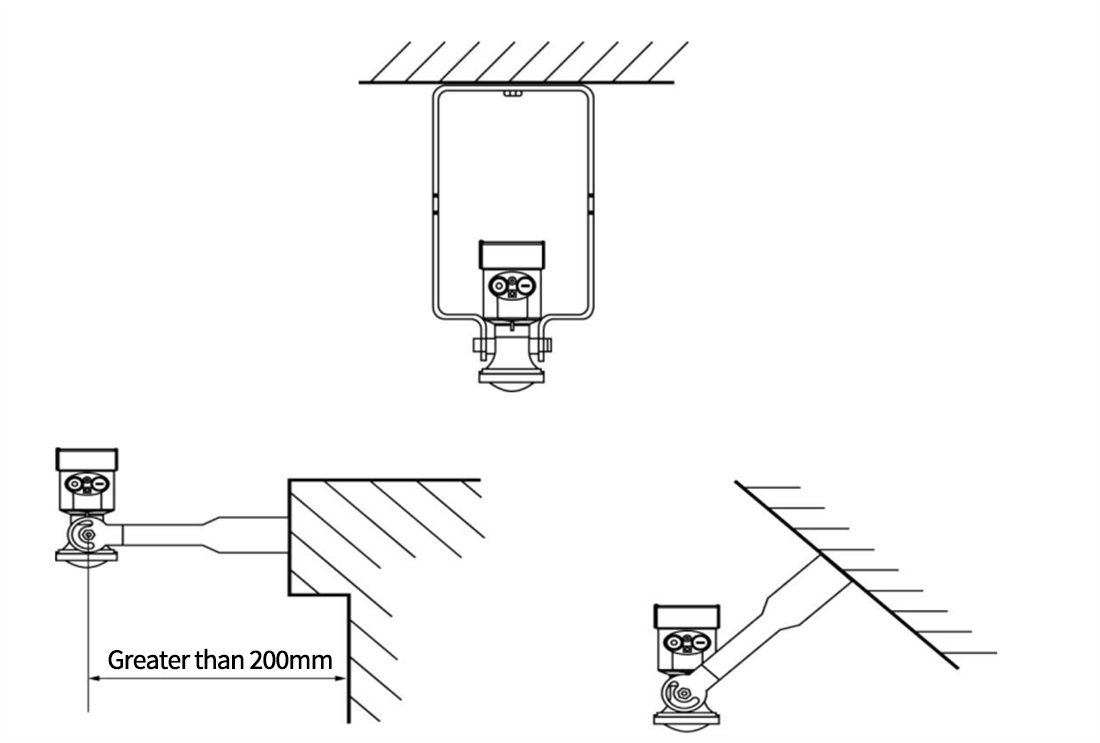

Способ установки 3: подъемный

(выбирается в зависимости от конкретных условий установки)