- Início

- Produtos

-

Medição de caudal

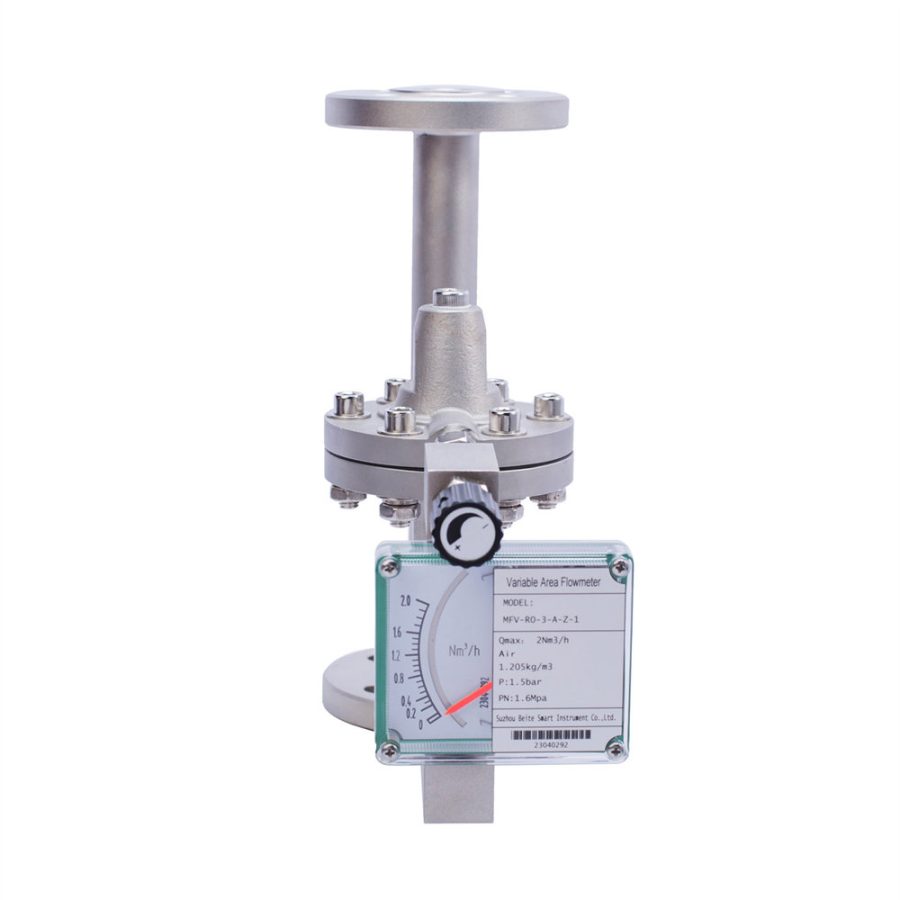

Medidor de caudal de área variável Medidor de caudal eletromagnético Medidor de caudal Vortex Medidor de caudal de turbina líquida Medidor de caudal para turbinas a gás Medidor de caudal de rotor de vidro Rotâmetro de plástico Medidor de caudal mássico Coriolis Medidor de caudal mássico térmico Medidor de caudal ultrassónico Caudalímetro de painel Caudalímetros miniatura de área variável Medidor de caudal de engrenagens Medidor de caudal de engrenagem de deslocamento positivo Medidor de caudal com impulsor Medidor de caudal de vórtice de precessão Medidor de caudal de orifício Medidor de caudal Annubar Medidor de caudal com deflector Medidor de caudal de rotor de alta pressão Medidor de caudal de rotor com corpo de plástico Dispositivo de corrente constante Válvula de caudal constante Filtro magnético

- Medição de nível

- Medição de pressão

- Medição da temperatura

- Instrumentos de visualização

- Interruptor de caudal

- Indicador visual de visão

- Monitorização do ambiente atmosférico

-

Medição de caudal

- Sobre nós

- Solução

- Notícias

- Contacto