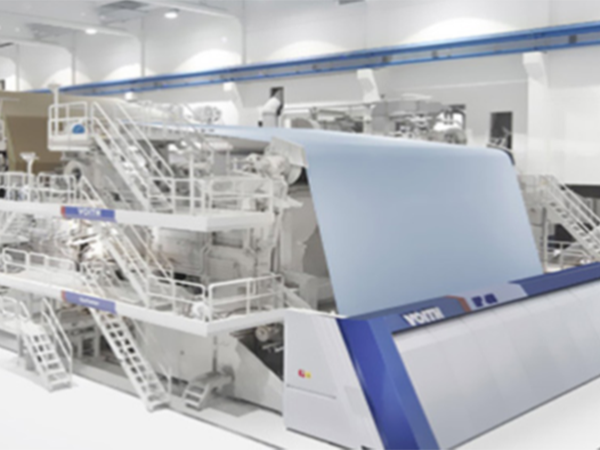

Application of Beite electromagnetic flowmeter in the paper industry

In recent years, with the increasingly strict environmental protection laws, most paper companies have established waste liquid treatment processes. Surveys have found that electromagnetic flow meters are used in almost all sections of paper mills.

The main task of the material preparation section is to make pulp from different principles. Electromagnetic flow meters mainly participate in the flow measurement of polishing slurry, water, and acid or alkali during the pulp making process. The temperature of the polished slurry should reach 80 ℃. When raw materials are used for pulping, they need to go through the steaming and boiling process. Due to the alkaline nature of the cooking solution, such as Ca (OH) 2 or NaOH solution, electromagnetic flow meters often use high-temperature resistant PTFE lining and split structure. Currently, many enterprises use waste paper pulping, and the pulp needs to be washed and bleached. Here, electromagnetic flow meters are mainly used to measure the water flow rate after participating in pulping. Most of the water is from nearby river water that has been slightly treated before participating in operation, so the water quality is poor, but it is not corrosive. The electromagnetic flowmeter can use conventional rubber lining and stainless steel electrodes; When measuring the de ink agent involved in the de ink process, the selection of electrodes and liners for the electromagnetic flowmeter should be carefully considered.