Product Features

Strong adaptability: Different electrical parameters of the measured liquid have no effect on the measurement, and harsh conditions such as scaling, turbulence, agitation, bubbles, medium viscosity, high pressure, etc.

Conditions have no effect on the detection.

Maintenance-free: No moving parts, simple to use, sturdy and durable.

No need for adjustment: Not affected by the electrical parameters of the measured medium, no regular debugging is required.

Power-off data storage: High and low position power-off protection, safe and reliable.

Main technical indicators

Power supply: DC 24VDC; AC 220VAC, 50/60Hz

Working temperature: -20~200℃

Output mode: DPDT relay contact output, RS485 communication (optional)

Contact capacity: 220VAC 5A

Explosion-proof grade: Intrinsically safe type: ExiaIICT4-CT6

Flameproof type: ExdIICT4-CT6

Application range

It is suitable for high and low level detection of various materials/liquid media in tanks or pipelines. The product is widely used in fiber industry, rubber industry, tire industry, cement industry, steel industry, food factory, pharmaceutical factory, petrochemical factory, feed factory, etc. The liquid level control of raw material/process/finished product tanks in industries such as fiber industry, rubber industry, tire industry, cement industry, steel industry, food factory, pharmaceutical factory, petrochemical factory, feed factory, etc.

Product parameters

| UYK100 standard type |

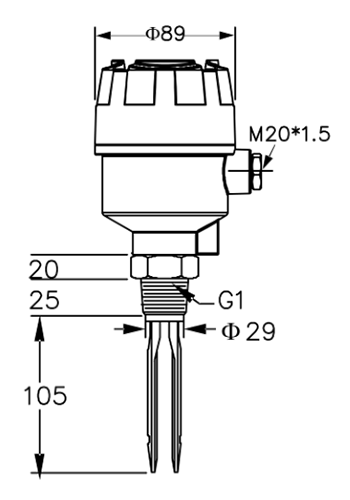

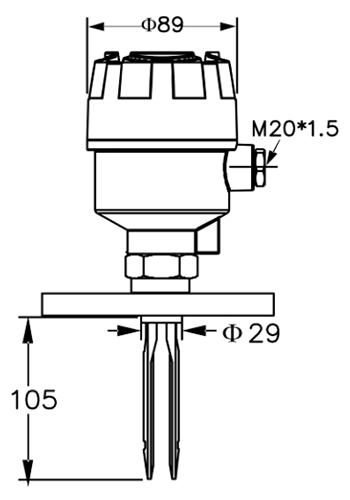

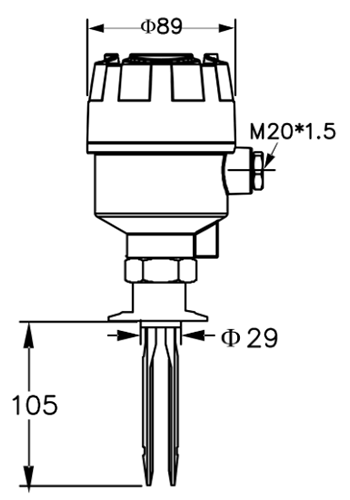

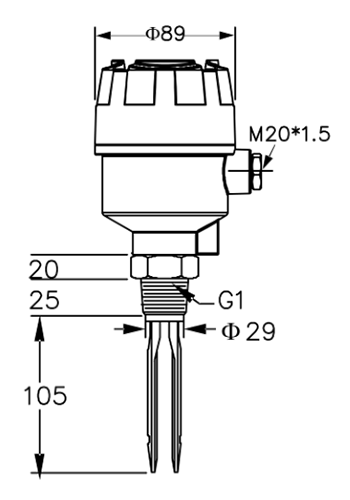

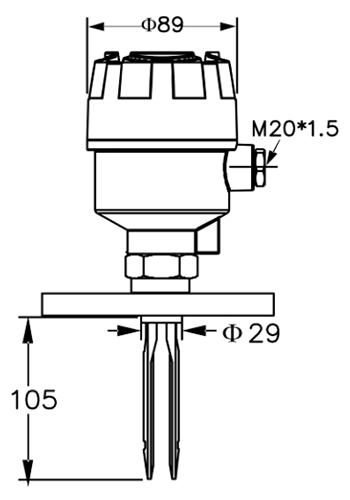

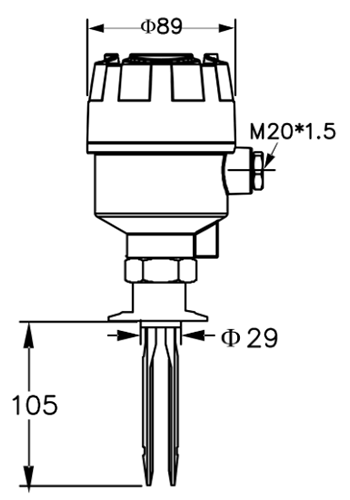

Dimensional drawing

(Unit: mm) |

|

|

|

| Model |

UYK100 Threaded type |

UYK100 Flange type |

UYK100 Sanitary joint type |

| Junction box material Protection level |

Aluminum alloy paint/IP65 |

| Tuning fork rod material |

SUS304/316/316L |

SUS304/316 Coated TEFLON |

SUS304/316/316L |

| Continuous specification |

G1 thread |

Flange minimum DN32 |

50.5 sanitary joint |

| Line inlet |

M20*1.5 |

| Maximum vertical bearing capacity of tuning fork rod |

177in.Lbs(20Nm) |

| Process pressure |

Vacuum ~600PSI(40BAR)110/220Vac, 50/60Hz |

| Power supply |

18~36 Vdc |

| Power consumption |

5W |

| Ambient temperature |

-40℃~85C |

| Process temperature |

Normal -40℃~85℃/high temperature MAX180℃/Special specification 240℃ |

| Output contact |

Relay, DPDT, 5A / 250Vac / 28Vdc, 1 group or 2 groups SSR (MOSFET) 400mA / 60 Vac / Vdc, 1 group or 2 groups |

| Minimum induction density of fork rod material |

Powder: ≥0.07g/cm3 Liquid: ≥ 0.7g/cm3 Viscosity: 1~10000 cSt |

| Action delay |

0.6 seconds action; 1~3 seconds - reset |

| Vibration frequency |

350~370Hz |

| High and low position failure protection device |

High, low |

| Sensitivity |

High, low |

| Length |

Conventional 100-1500mm, (Except for extended split) |