Product Introduction

The BTLZ series intelligent metal tube rotor flowmeter has various measurement forms. According to the output form, it is divided into local indication type, remote transmission output type and control alarm type. According to the explosion-proof requirements, it is divided into ordinary type, intrinsically safe type and isolated explosion-proof type.

Its design and production provide installation methods such as bottom in and top out, top in and bottom out, side in and side out, bottom in and side out, and horizontal installation. It can be equipped with 4~20mA remote transmission output (with HART communication), pulse output, upper and lower limit alarm output and other functions. This intelligent signal transmitter has high accuracy and high reliability, and can replace imported instruments of the same type with high cost performance.

Product Features

1. Strong metal structure design

2. Suitable for various industries of gas and liquid measurement

3. New flow shell structure design, it can be used in high temperature environment without increasing components.

4. Special design of conical measuring tube, its measuring range and measuring linear are wider and better.

5. We can offer flange connection, clamp, thread and other process connection modes, which is suitable for most of the factories application requirements.

6. Measuring part materials can be selected: stainless steel, titanium, Hastelloy, PTFE, FEP, etc

Technical parameters

| Measuring range |

Water 16~150000 L/h

Air 0.5~4000 m3/h |

LCD display |

Instantaneous flow

Cumulative flow |

| Jacket pressure rating |

1.5~42MPa |

Electrical interface |

M20×1.5、 PG11、 1/2”NPT |

| Medium temperature |

Standard: -80℃~+220℃ |

Overall height |

Standard type: 250mm |

| High temperature type |

300℃ |

Protection level |

IP65 / IP66 / IP67 / IP68 |

| Lined FEP type |

≤85℃ |

Explosion-proof mark |

Intrinsically safe type: ExiaIICT3~6

Flame-proof type: ExbdIICT4~6Gb |

| Ambient temperature |

-40℃~+120℃ |

Medium viscosity |

DN15: ≤30mPa.s

DN25: ≤250mPa.s

DN50~DN150: ≤300mPa.s |

| Range ratio |

10:1 (special type 20:1) |

Signal output |

Standard : 4~20mA

Alarm : 1. Two relay outputs

2. One or two-way

Pulse : 0-1KHz |

| Accuracy |

2.5%FS 1.5%FS 1.0%FS |

Power supply |

24VDC±20%

220VAC

lithium battery |

| Working pressure |

PN16MPa (Special type 42MPa)

PN10MPa (Special type 25MPa) |

Connection method |

Flange or Threaded |

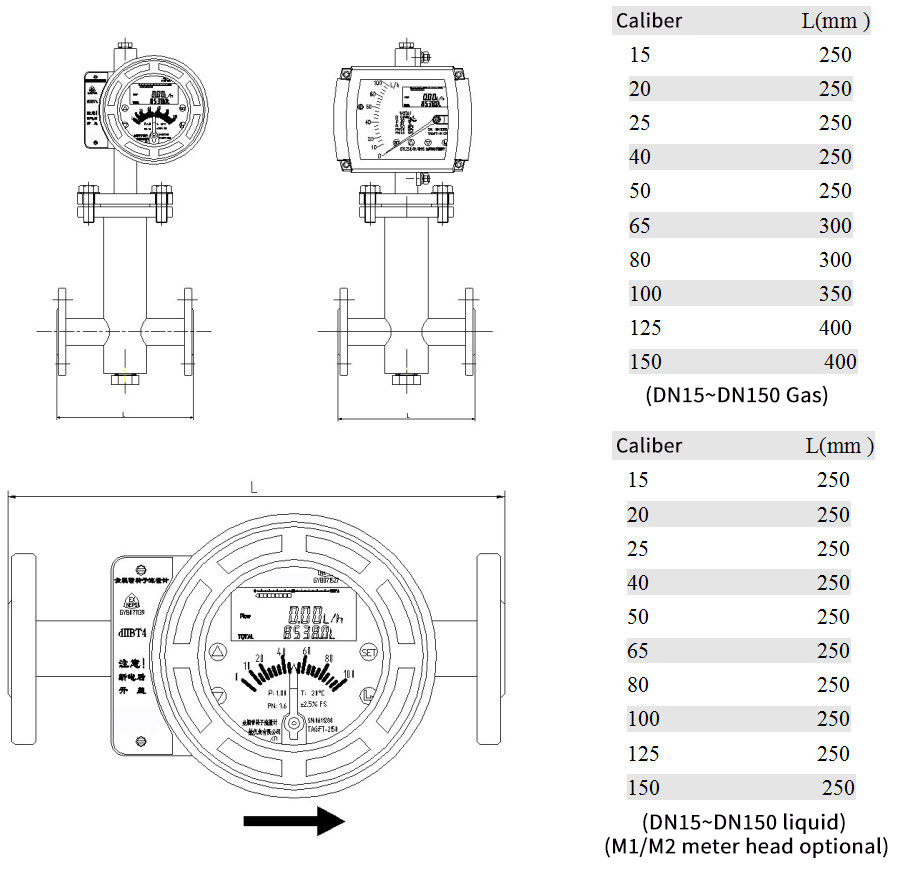

Product size

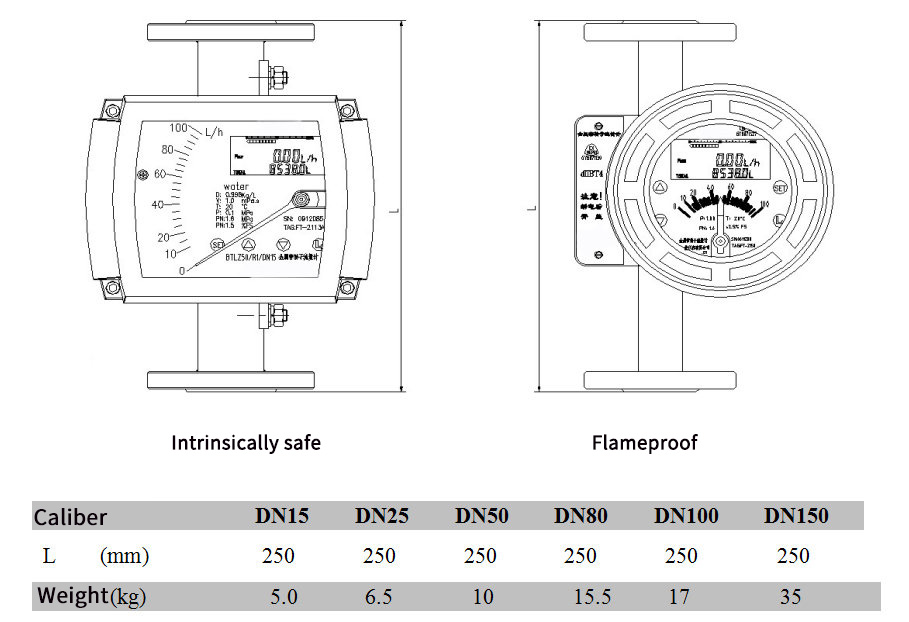

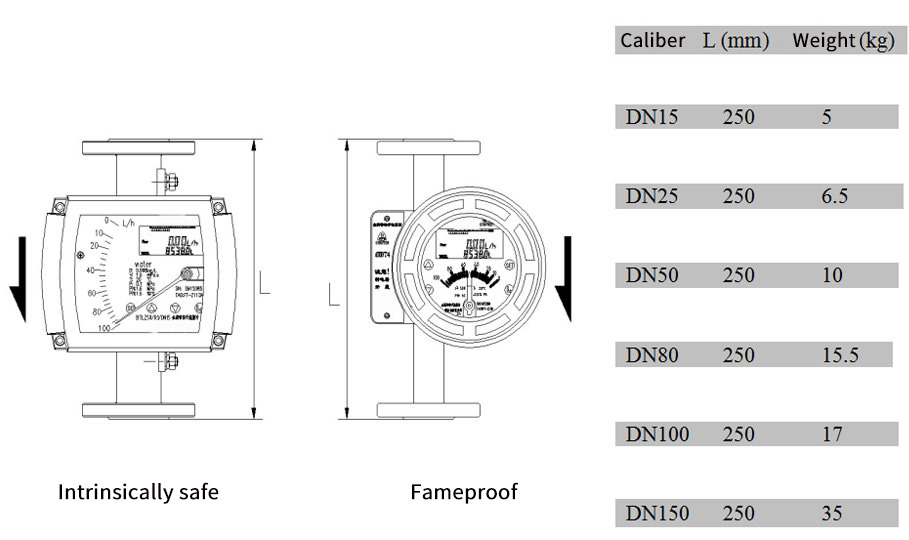

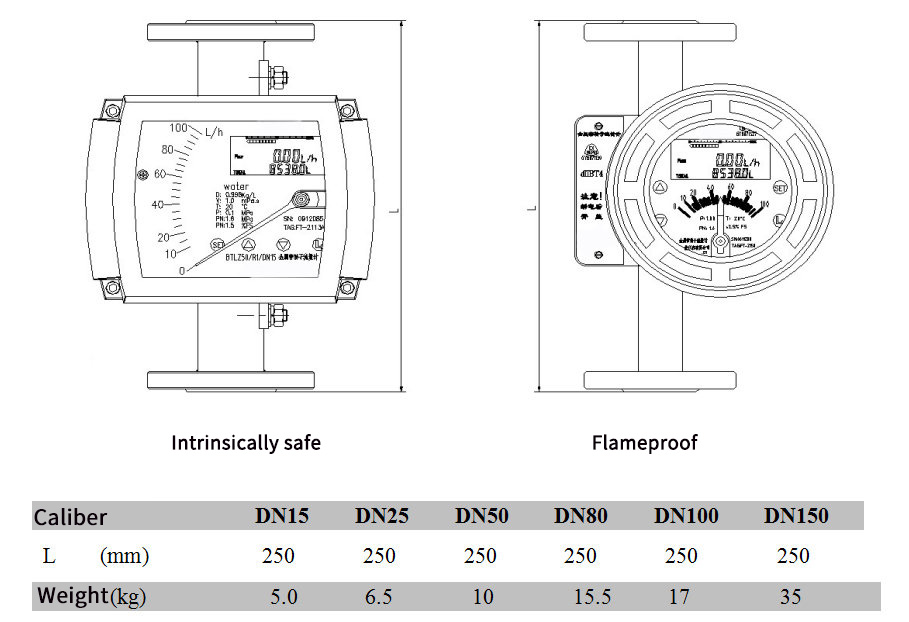

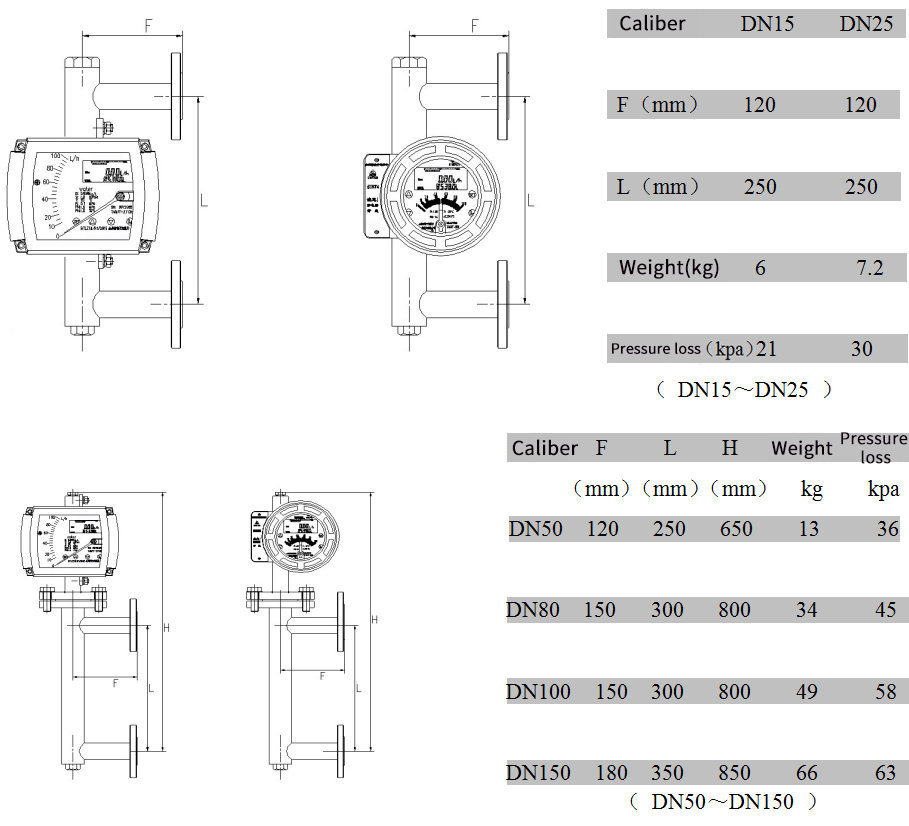

Standard dimensions and weight

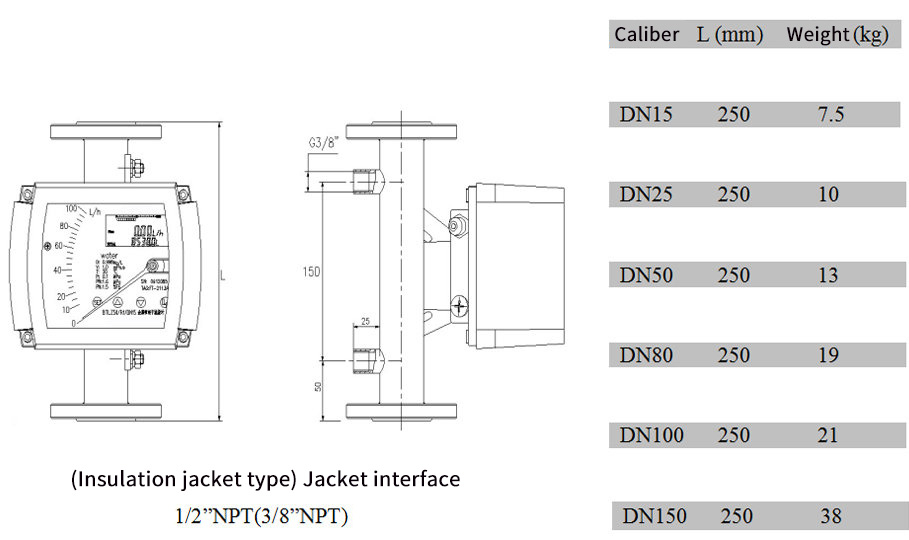

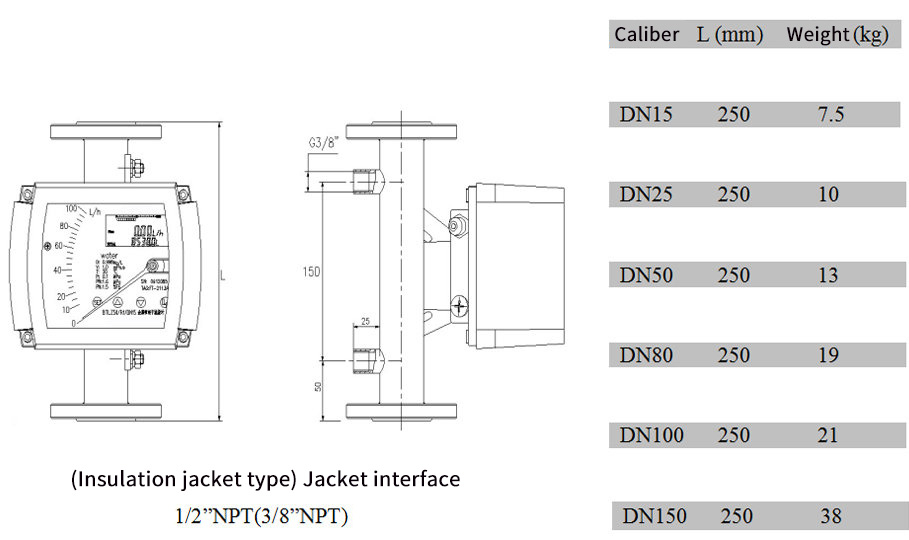

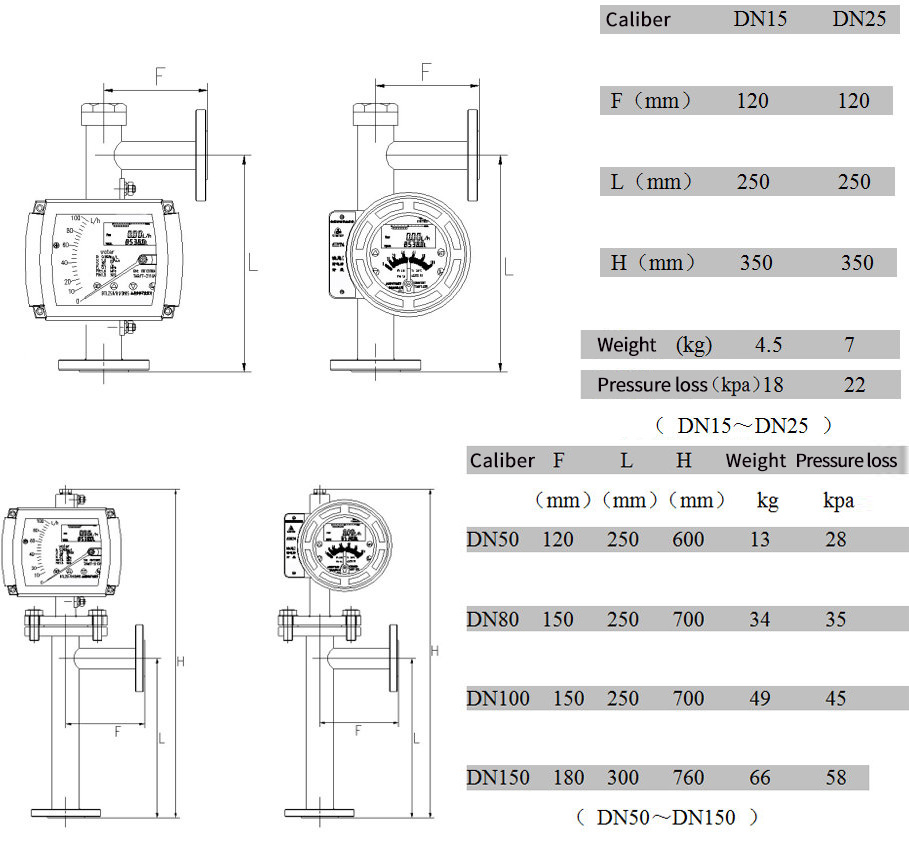

Jacketed Dimensions and weight

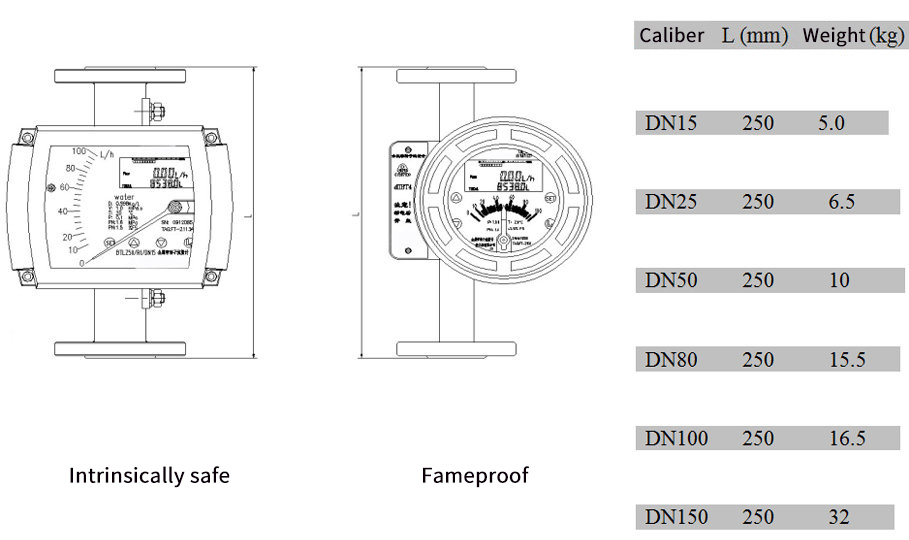

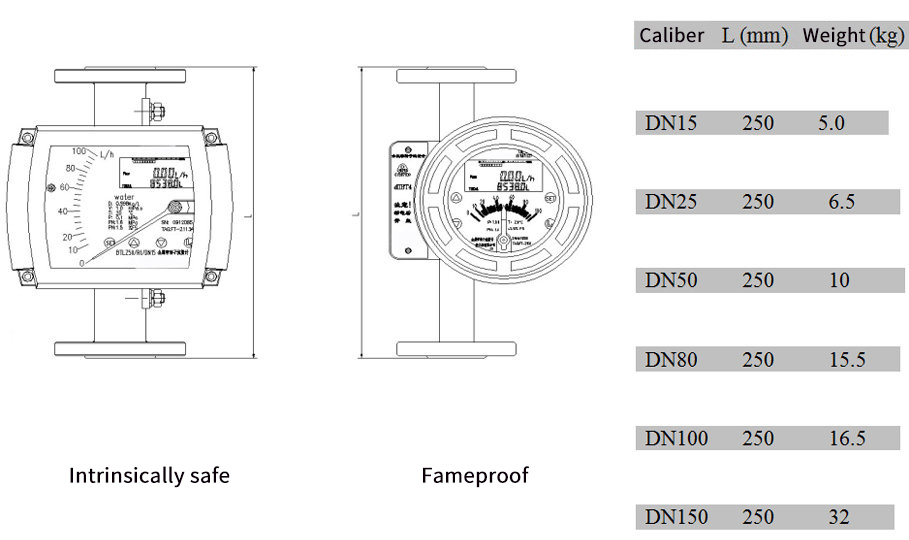

FEP Liner type Dimensions and weight

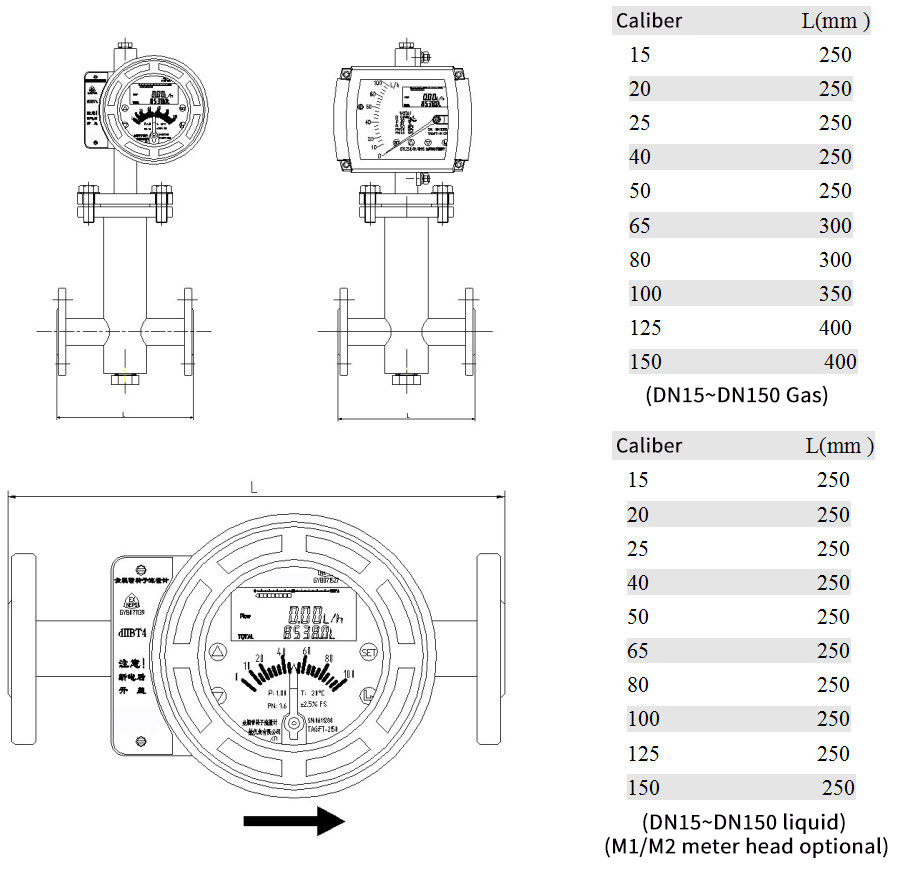

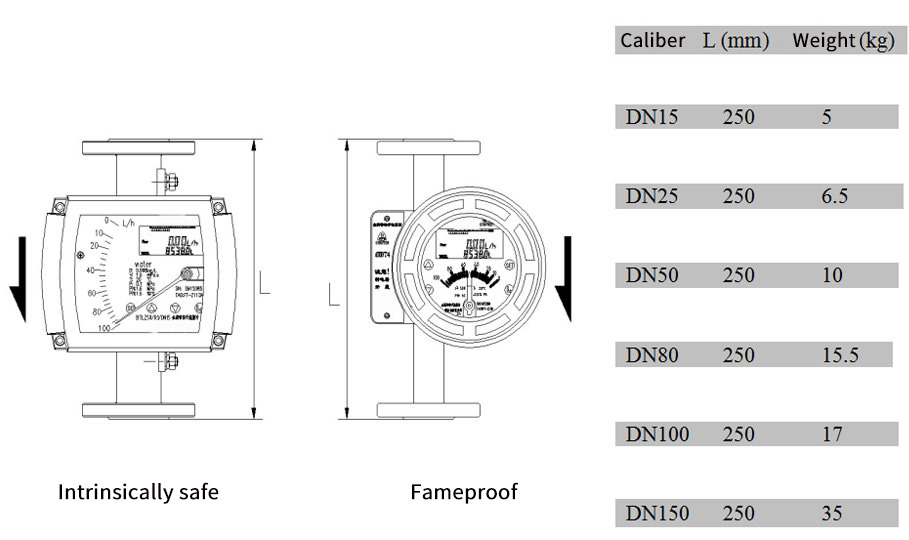

Vertical outlet type Dimensions and weight

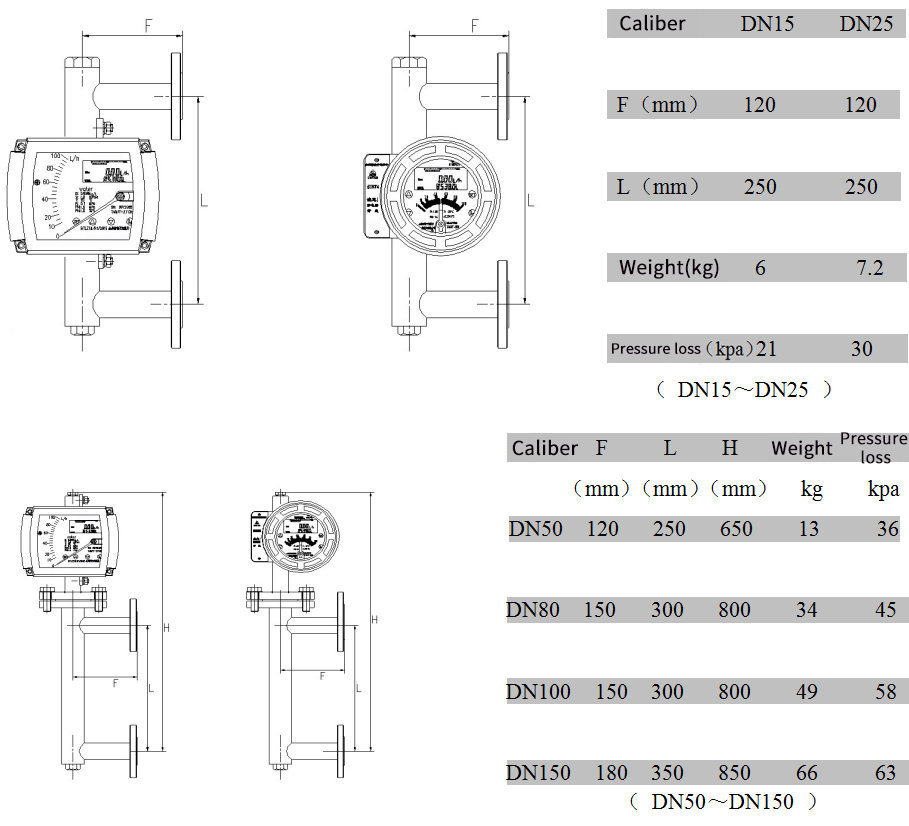

Side aisles outlet type:Dimensions ,weight and pressure loss

Bottom inlet and side outlet type:Dimensions ,weight and pressure loss

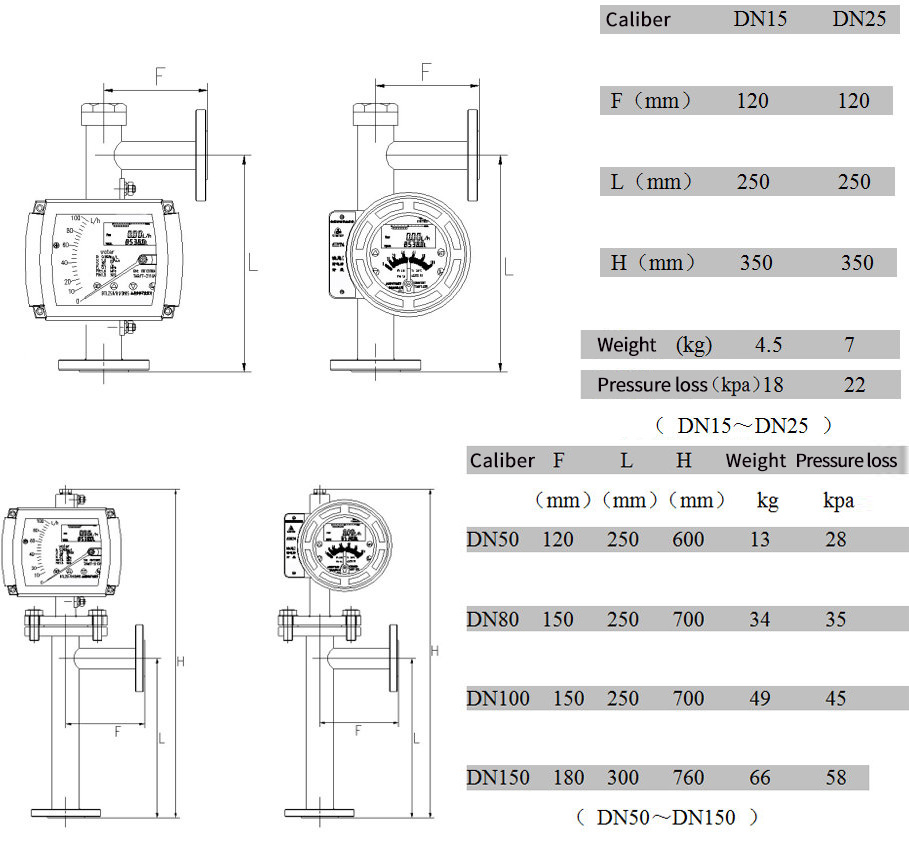

Horizontal mounting type:Dimensions ,weight and pressure loss